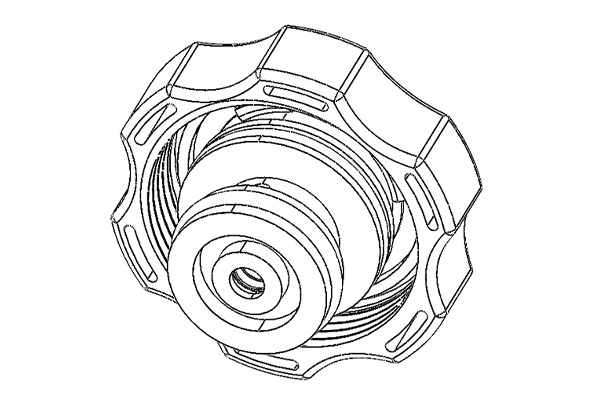

Pressure Cap

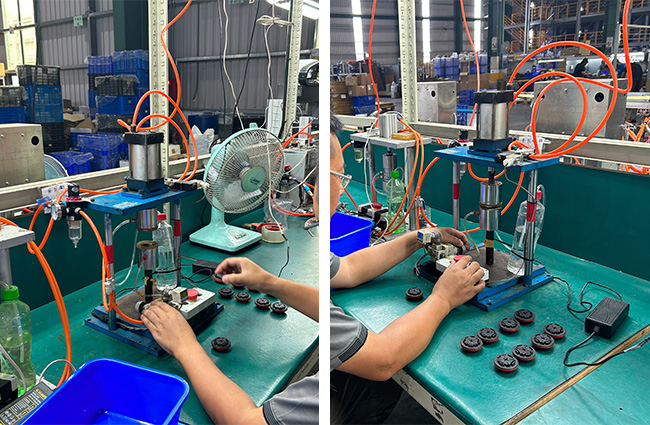

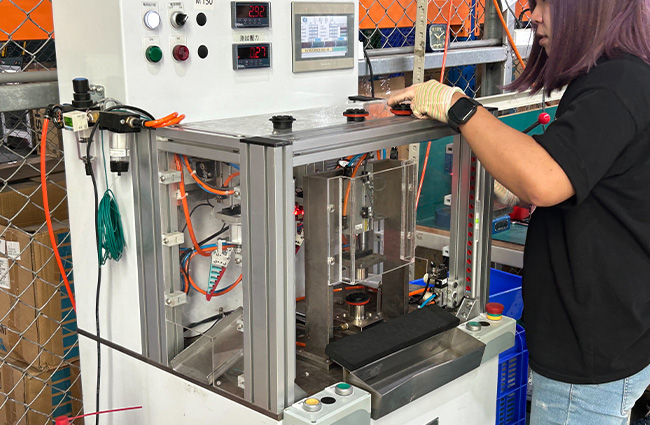

We pride ourselves on clearly distinguishing between filling caps and pressure caps. This classification showcases our dedication to precision engineering, The caps haven supported by our rigorous equal-checking process that adheres to OE (Original Equipment) standards.